The Effects of Corrosion and Scale

I know many of you have dealt with some kind of corrosion or scale issue, but perhaps you have never heard about how the efficiency of a heating system is affected by corrosion or scale build-up.

I think my first exposure to the term corrosion came when I was a little younger and my ‘52 Ford failed to start. My friend’s dad, a crackerjack mechanic, came by to see what the problem was. I would guess by now you all know that the no-start condition was caused by battery terminal acid corrosion. He also taught me that baking soda mixed with H2o would help to dissolve the acid.

Often, sacrificial anode corrosion occurs from an electromechanical reaction within a water heater. The reaction causes the rod to deteriorate and this helps to extend the life of the water heater. Did you ever see what an anode rod looked like after being in a water heater for several years? Depending on the water condition, probably 50% of the rod may be deteriorated. There are two types of anode rods—magnesium or aluminum—and larger heaters will generally have two rods. Keep in mind that manufacturers of water heaters do not all use the same type of rod, and that it’s helpful to be able to identify the type of rod you’re dealing with.

The aluminum rod will most likely have a flat head and the magnesium rod will have a slight bump on the head. Keep in mind also that when piping a water heater a steel nipple attached to copper will corrode faster, so always create a dielectric separation. The zinc anode is another product that is often placed on the lower end of a marine motor skeg, to prevent it from corroding when exposed to salt water for long periods. The zinc will react much like the anode rod and extend the life of the unit. However, it can be visually inspected, unlike an anode in a water heater, and replaced on an asneeded basis.

Corrosion and scale can be found within the heating distribution system, especially if it has been installed for several years. Think about all those green, corroded valves and fittings that you’ve seen during your many years in the trade. I know that there are times when you said to yourself, “I’m not touching that valve.”

For years a heating system may perform very well, but then the customer calls to say the system is not providing enough heat. Do we know why? Could it be that scale build-up in the distribution piping is the culprit?

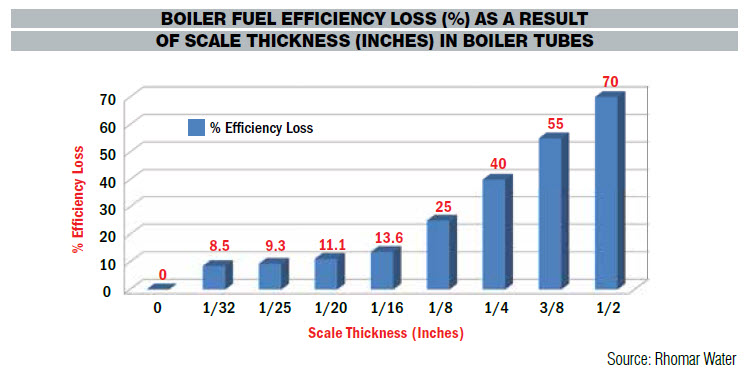

I’m also finding more manufacturers are recommending boiler treatment as a regular service in order for the system to operate at maximum efficiency. I have included a graph by Rhomar Water, the provider of heat transfer fluid, that addresses fuel efficiency loss due to scale.