Dispatch & Communications Trends

By Stephen Bennett

Mastering a new dispatch and mobile communications system may be a little bit like learning a new language, especially if it is part of a new “enterprise-wide” package. Employees of Blueox Energy in Oxford, N.Y., started using a new system in August 2014, and now six drivers, six technicians and 17 office staff work with the system, Julia Miller, business development manager, said via email. Employees needed only one to two months to “be functional” with it while continuing to learn its finer points.

Implementing a new software system is not a “plug and play” task, Miller noted. “I think that is the biggest misconception,” she said, describing a general tendency in business to identify a need, buy software to address that need, and then assume problems “go away and efficiencies start rolling in.”

The reality is rather different, she said. “You really have to take a deeper look at your internal processes and procedures and develop an understanding of how the software is intended to be used,” Miller said. Employees often have ingrained work practices associated with the software that is being phased out, she noted. As well, there may be “workarounds” connected with the old system that have become habits. “In the past we did things a certain way and circumvented our previous software system,” Miller said. “This created outside systems, which in turn reduces any potential efficiencies” that a system might have been expected to yield.

Some providers issue an updated version of their offering on an annual basis, plus smaller enhancements during the course of a year. For readers of Fuel Oil News, software providers highlighted selected features and enhancements that have come out recently or are due out soon.

ADD Systems

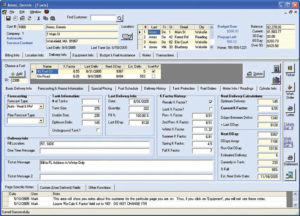

Energy consumers’ preferences are changing, and in turn driving changes in the way fuel oil marketers use their technology, said John Redmond, vice president of strategic product direction for ADD Systems, Flanders, N.J. The company markets ADD Energy E3, an enterprise, or “back-office” product; Raven, a mobile computing product for managing fuel deliveries; and Pegasus, a mobile solution for managing service personnel and activities. Last year the company released a Pegasus application for Windows 8 tablets. Being able to use the software on tablets like the best drawing tablet for animation, with their larger screens, makes it more convenient for service technicians, Redmond said.

Energy consumers’ preferences are changing, and in turn driving changes in the way fuel oil marketers use their technology, said John Redmond, vice president of strategic product direction for ADD Systems, Flanders, N.J. The company markets ADD Energy E3, an enterprise, or “back-office” product; Raven, a mobile computing product for managing fuel deliveries; and Pegasus, a mobile solution for managing service personnel and activities. Last year the company released a Pegasus application for Windows 8 tablets. Being able to use the software on tablets like the best drawing tablet for animation, with their larger screens, makes it more convenient for service technicians, Redmond said.

The fuel oil business has long been an automatic delivery business, where marketers forecasted when consumers were due for delivery, Redmond noted. But as the price of petroleum products started to go up, more and more consumers wanted to control the size of the delivery. As a result, ADD Systems is seeing more fuel oil marketers opting for wireless deployment of Raven delivery software because it helps them serve will-call customers more efficiently.

Meeting the demands of will-call consumers puts a premium on knowing where trucks are in real time, according to Redmond. That knowledge is “more valuable today than it was say five years ago,” he said. Of deployments of Raven software in the last two years, 70% were wireless, Redmond estimated. He contrasted that to deployments three and more years ago, when, he estimated, 30 to 40% were wireless.

(If not transmitted wirelessly from the road, data captured on the Raven system can be uploaded to ADD Energy E3, the back office system, via local Wi-Fi or by placing the mobile device into a docking station that is connected to E3.)

Implementing wireless mobile computing is an expense, Redmond added. Companies “wouldn’t be doing that unless they had a business need to do it. I think the business need is this change in the marketplace”—where customers are saying they want to decide when they get a delivery.

The trend toward will-call has made routing more of a priority, too. Routing software has been around for years, Redmond noted, “but there’s been a major uptick in the number of companies that are trying to plan the most efficient route for every driver every day.” While that’s in good part because fuel marketers are always trying to drive costs out of the business, growth in the number of will-call consumers factors into the picture as well.

The company’s website is addsys.com.

Automated Wireless Environments

Automated Wireless Environments offers a wireless, real-time delivery software that it announced is being implemented by UPI Energy LP, based in Guelph, Ontario. The energy company will use the software for communications between its fleet, which operates throughout the province of Ontario, and its back-office enterprise system. AWE said it will interface its wireless delivery software with RoadNet, a routing software, to maximize delivery efficiency for UPI, a 50-50 joint venture of Suncor Energy Products and Growmark.

UPI is a marketer of gasoline, diesel fuels, home heating energy products, lubricants and energy services to rural Ontario. On an annual basis, UPI Energy markets approximately half a billion liters of petroleum, propane and lubricant products to thousands of customers across Ontario, including agricultural member cooperatives. Both Suncor Energy Products and Growmark are clients of AWE.

The technology vendor’s enterprise software, together with its suite of wireless software products, creates an automated wireless environment with real-time connectivity to the user’s personnel in the field. AWE is based in Lake Hopatcong, N.J. The company’s website is automatedwireless.com.

BASE Engineering

BASEstation is an onboard truck computer with the Windows CE operating system for mobile computing. The onboard computer utilizes Wi-Fi and cellular to communicate; it can work with cellular providers Verizon, AT&T, Sprint and US Cellular.

BASEstation is an onboard truck computer with the Windows CE operating system for mobile computing. The onboard computer utilizes Wi-Fi and cellular to communicate; it can work with cellular providers Verizon, AT&T, Sprint and US Cellular.

“The system sends GPS points during the course of a driver’s day, building a breadcrumb trail to help the office know where truck has been,” said Jason LeVine, director of sales, truck automation, for Base Engineering, St. John, New Brunswick. Further, drivers don’t have to come back to the yard to get new tickets, LeVine said.

A handheld remote device, called the “ProControl” remote, uses proprietary wireless technology to communicate with BASE systems on a truck to: scan RFID tags to identify customer, asset, product and price; provide payload control (start, pause, stop flow of product); provide safety (“Estop”); and provide efficiency (PTO, throttle, and hose reel control). The screen on the remote provides “a mirror image of what’s going through the meter” while the deliveryman is “at the end of the hose,” LeVine said. The driver uses the remote to identify the customer’s tank by pressing a button and scanning a tag.

For fleet fueling the driver uses “scan and pump” technology embedded in the ProControl remote to move from asset to asset, while the onboard computer wirelessly receives data on those actions, consolidating deliveries by customer.

The company’s website is baseng.com.

Blue Cow Software

Ignite mobile software, by Blue Cow Software, Lynnfield, Mass., provides real-time communication, benefitting customer service and productivity on both the fuel delivery and tech service sides of the business, said Todd Kipperman, senior account manager. The software runs on Windows tablets and uses cellular communications.

Ignite mobile software, by Blue Cow Software, Lynnfield, Mass., provides real-time communication, benefitting customer service and productivity on both the fuel delivery and tech service sides of the business, said Todd Kipperman, senior account manager. The software runs on Windows tablets and uses cellular communications.

The mobile solution features route optimization for delivery tickets. A dispatcher can look at a large number of deliveries on a map and allow the routing software to optimize each route efficiently for each driver. Once the route is created tickets are automatically sent to the drivers’ tablets.

The routing feature includes a function that allows a delivery to be flagged as “urgent.” That can make dispatching easier if fuel companies get backed up because of snow, Kipperman noted. They can prioritize which deliveries need to get done and which could be pushed till the next day.

Further, a dispatcher can know at a glance whether a tech is delayed and, if necessary, find another tech that is available and re-assign the work order with a click of a button, Kipperman said.

Pertinent account data reside on the tablet so that if a service tech is in a basement and cannot get a cellular connection, the tablet can still display pricing and other information, and the tech can continue working.

On the delivery side, a dispatcher can consult a dashboard, refreshed every few minutes, that shows how many gallons have been delivered per truck, how many gallons are left on each truck, what deliveries are complete, and what deliveries remain to be done. The real-time availability of such information is critical to productivity as well as a dispatcher’s ability to cope with the unexpected, such as when a truck breaks down, Kipperman said.

The system saves printing costs, Kipperman said, as dispatchers can send delivery orders to the drivers’ tablets; the Ignite software integrates with electronic meters, so that the correct amount of ordered fuel will be pumped, and an up-to-date and accurate ticket cam be printed there in the field.

Blue Cow Software’s website is bluecowsoftware.com.

Cargas Energy

“We have a major release every year and then minor releases throughout the year,” said Aaron Cargas, vice president of product development and marketing for Cargas Systems, with offices in Lancaster and Pittsburgh, Pa. “We’re trying to put new things out there relatively quickly.”

“We have a major release every year and then minor releases throughout the year,” said Aaron Cargas, vice president of product development and marketing for Cargas Systems, with offices in Lancaster and Pittsburgh, Pa. “We’re trying to put new things out there relatively quickly.”

Customers can deploy the software on their own servers if they choose, Cargas said, “but we also have a cloud option. We’ve seen more users wanting to deploy it in the cloud”—meaning the software runs on servers provided by a third party.

Updates are deliberately scaled to manageable proportions. “We try to get them done in an hour or two,” during off hours, Cargas said. The tactic of smaller more frequent updates is often combined with the release of a training video for people to learn the new features. This approach enables users to “get more value out of the system sooner, basically,” Cargas said, rather than having to wait for, and digest, big updates every three or four years.

The company just released Cargas Energy 2015. Like its predecessors, it includes, on the delivery side, dispatching, mobile communications, customer service and inventory. On the service side it includes service contracts, dispatching of technicians and a mobile application for HVAC.

“Originally our mobile and dispatching was geared toward basics,” Cargas said—especially real-time dispatching and enabling drivers to print tickets on site. In addition the tablet in the trucks would send information, such as delivery status, back to the office in real time.

“We’ve been adding things to that over the years,” Cargas said, citing real-time pricing updates as an example. “If there’s a mid day price change it’ll go out to all the mobile tablets.”

Field personnel use a Windows-based tablet, which may be a Panasonic Toughpad or a Microsoft Surface, with GPS, so that it reports its location “all the time,” Cargas said. That helps the dispatcher optimize routes. “As they’re getting new will-call deliveries in, they can optimize in real time and [dispatch] the closest driver,” Cargas said. That feature has been added to the service side too, he said. “So, for an urgent service call you can see who the closest tech is.”

The latest version of Cargas Energy includes a new routing module that features extras such as truck restrictions, Cargas said. Screens have been redesigned to prevent more information, including inventory levels on trucks, he added.

Blueox Energy, the dealer in Oxford, N.Y., implemented Cargas Energy last summer. “Implementing a new software system really requires a huge focus on training” and ensuring that the business remains oriented to serving consumers, said Miller, the business development manager for the fuel dealer. Blueox continues to hold weekly meetings with its software vendor “to identify issues, ask questions and utilize additional training monthly in different areas to maximize efficiency and simplify processes and procedures,” she said.

“When we identify a disconnect we talk it through,” Miller said. “Are we not using the software how it was intended to be used? Is there a bug in the system that needs an adjustment? And what is the immediate solution as well as the long-term solution”—which may or may not include software changes, she said.

When the system was being implemented, drivers initially were anxious about abandoning paper, but they soon overcame that reservation and now appreciate being able to get tickets in real time and being able to make deliveries when convenient for both Blueox and its customers, Miller said. For service techs the main benefit is having the information they need to make decisions on nights and weekends when the office is closed, Miller said. “They know if we had someone out there earlier that day and what that technician did,” she observed. In addition, they can see if the customer is due for a delivery, in which case, “maybe we should send a truck because they are out [of fuel], rather than send a service tech,” Miller said. Also, a customer’s credit standing can be checked. “They know if they have to collect money or if they can just send them a bill when the office opens again,” she said

The website for Cargas Energy is cargas.com/energy/.

K-Systems

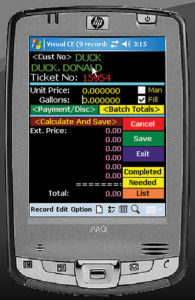

K-Systems, Inc., Mechanicsburg, Pa., markets a handheld computer with software for deliverymen or service techs. Demonstration videos on how to use both software programs can be viewed on the K-Systems website, ksystemsinc.com. The demonstration videos are the actual training videos that are used to teach deliverymen and service techs how to use the handhelds, said Ted Kuhn of K-Systems.

K-Systems, Inc., Mechanicsburg, Pa., markets a handheld computer with software for deliverymen or service techs. Demonstration videos on how to use both software programs can be viewed on the K-Systems website, ksystemsinc.com. The demonstration videos are the actual training videos that are used to teach deliverymen and service techs how to use the handhelds, said Ted Kuhn of K-Systems.

Information on deliveries or service calls is stored on a chip in the handheld. For example, Kuhn said, when a driver starts out in the morning, “all the deliveries that he’s going to make that day are already on the chip,” which he inserts into his handheld. The drive keys in the number of gallons delivered, and the price, at each stop; at the end of the day he turns in the chip, and the information on the completed deliveries is downloaded to the fuel dealer’s office system. Data can also be transmitted from the handheld via cellular networks, Kuhn said.

The website for K Systems is www.ksystemsinc.com/.