Solid Ground

by George Lanthier

I would like to personally thank all of you that have written, sent e-mails and approached me at seminars about how great it would be to see the boys at B&B Mechanical again. These guys have reached a point where they have become legends and to see the boys back at work again would be nice. I will tell you honestly that the compliments are flattering and I also have missed their exploits as much as you have. The problem is we retired Bruce and moved Bubba to the local Fire Department.

We’ve dusted off and updated an old article and so we’re going to go back on one of their favorite adventures for now and I’m working on a new job (article) from the past too! By the way Bruce is enjoying his retirement and is having a great time, fishing, golfing and enjoying traveling, in other words enjoying his well-deserved departure from the job scene. Bubba’s still doing a little burner work on the side and has just made Lieutenant and is now the head guy on burner inspections, my how things change.

This article will take us back again to those great guys at B&B Mechanical. It’s a very cold morning and the guys are trying to get warm by drinking coffee and watching Bubba’s attempts to get the burner going in the shop.

“I can’t believe that on one of the coldest days of the year we have no heat here and no customers are calling; it’s amazing,” said Bruce.

“Yeah, isn’t that something Unk, and we just changed this control last night before going home,” whines Bubba.

“I don’t know why you had to change it,” said Bruce. “The burner was running fine and I still like my old controls. You just can’t beat interrupted ignition and that burner’s been running great since I put it in 20, no, 24 years ago.”

“We just wanted to up-grade it, Unk, so we put in a new solid-state job, that’s all. We didn’t eliminate your interrupted ignition. Geez, come to think of it, we even added an oil valve and picked up the pre-purge and post-purge you’re so fond of. I guess that’s what you get for trying to do the right thing,” said Bubba as he goes for another cup of coffee from the

by George Lanthier

I would like to personally thank all of you that have written, sent e-mails and approached me at seminars about how great it would be to see the boys at B&B Mechanical again. These guys have reached a point where they have become legends and to see the boys back at work again would be nice. I will tell you honestly that the compliments are flattering and I also have missed their exploits as much as you have. The problem is we retired Bruce and moved Bubba to the local Fire Department.

We’ve dusted off and updated an old article and so we’re going to go back on one of their favorite adventures for now and I’m working on a new job (article) from the past too! By the way Bruce is enjoying his retirement and is having a great time, fishing, golfing and enjoying traveling, in other words enjoying his well-deserved departure from the job scene. Bubba’s still doing a little burner work on the side and has just made Lieutenant and is now the head guy on burner inspections, my how things change.

This article will take us back again to those great guys at B&B Mechanical. It’s a very cold morning and the guys are trying to get warm by drinking coffee and watching Bubba’s attempts to get the burner going in the shop.

“I can’t believe that on one of the coldest days of the year we have no heat here and no customers are calling; it’s amazing,” said Bruce.

“Yeah, isn’t that something Unk, and we just changed this control last night before going home,” whines Bubba.

“I don’t know why you had to change it,” said Bruce. “The burner was running fine and I still like my old controls. You just can’t beat interrupted ignition and that burner’s been running great since I put it in 20, no, 24 years ago.”

“We just wanted to up-grade it, Unk, so we put in a new solid-state job, that’s all. We didn’t eliminate your interrupted ignition. Geez, come to think of it, we even added an oil valve and picked up the pre-purge and post-purge you’re so fond of. I guess that’s what you get for trying to do the right thing,” said Bubba as he goes for another cup of coffee. He really loves coffee that comes from a single group espresso machine commercial in a hot caramel latte.

Do you have any idea what the problem may be? Well, it could be several things, no doubt about that. But it could also be several problems all related to the same basic cause, improper grounding of the electrical components. I talk to a lot of people in this industry about things most of you wouldn’t bother talking about. Lately, I hear a lot about a particular problem that always leads us back to the same thing. That is simply, grounding. Improper grounding or non-existent grounding of electrical equipment doesn’t work. Sometimes it can injure or even kill.

When we did legal work we were very busy with grounding issues, including personal injuries, but it was not surprising, but always very sad to me. I’ve been fully aware of the dangers of grounding for a long time having something most oilheat techs don’t have; three years of vocational high school electronics training. After graduation, my first full-time job was for RCA in the Defense Systems Division and again the need for grounding safety was pounded into my young head. Next, it was the United States Air Force where I learned heating and again safety was banged into my head over and over again.

In 2013 we gave up all legal work, but before that a part of my living was made as an expert witness. As an expert we had been involved with several serious injury cases all caused by improper grounding of everything from boilers and burners to air-conditioning condensers. Some of these techs have been seriously hurt.

Now, many of you are sitting there thinking, “damn it, George, proper wiring is the duty of a licensed electrician.” Well, you’re right, but who put the last heating unit in? Can you honestly tell that guy in the mirror that you’ve connected every burner grounding screw (the little green one, Figure 1) you’ve come across?

Oh, I know, “the grounding will be made through the boiler.” Really, ever hear of Teflon™ tape? When DuPont® first created this stuff it was for use as an insulator and it still makes a great one.

The worst case of personal injury I’ve heard of was a guy injured working on an industrial boiler where the connections to the system and water lines were all made in Teflon™ tape. It was a beautifully laid out and installed job, but electrically it was an electric chair waiting for its next victim. You just can’t keep breaking my second rule and getting away with it: Assume nothing!

Enough on safety, it’s your precious life on the line and all the soap boxing by me isn’t going to change a non-believer. Now, back to the equipment.

Today’s equipment contains more solid-state components, microprocessors, resistors, diodes, rectifiers and capacitors than you can shake a stick at, all of it requiring proper grounding. It’s not just primary controls either; it’s electronic ignitors, system controls and thermostats, too. A lot of the problems that you are running into are due to grounding.

When working as an expert witness I was associated with a gentleman by the name of Bill Werner. Bill is a genuine expert on electricity and when we talk about grounding he gets excited.

“Grounding is called out in every code and must be done properly for public and personal safety, and then everyone is amazed the stuff works right too,” Bill said. “If you work on equipment, you must check your ground.”

In the middle 1960s, UL demanded that OEMs provide for proper grounding and those little green screws showed up. When a piece of equipment is designed and tested, proper grounding is on the job. When warranties go back and the control you took off as not working now works in the factory it’s your fault. Keep in mind that at the factory those OEM test benches are to the book and grounded. One thing I notice a lot is that in conversations guys admit that they “took off the new stuff, put on ol’ reliable and it worked great.” There are only two problems with that statement: ol’ reliable won’t do as many things as the new ones, and they are also not as sensitive to grounding. There’s just less of or no solid-state in those ole-time boxes.

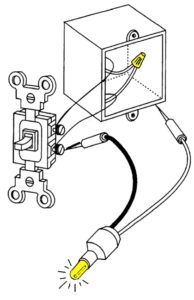

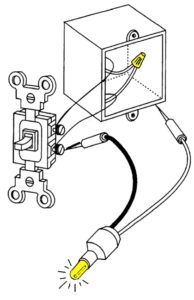

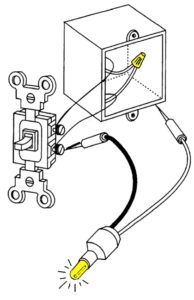

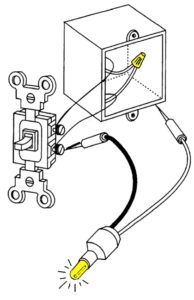

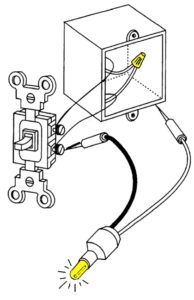

Proper grounding is very easily verified, but do you know how? Well, here’s my most favorite way. First of all, take a common light-bulb holder, one of my all-time favorite pieces of test gear. Take it and put it across a known circuit, it should light. Then, put it between your hot or power (L1) line and your neutral (L2) line, it should light again. Now, put it between hot and ground, Figure 2, again it should light and that proves your ground. Finally, put it between ground and neutral and it should not light. If it does, you have a short circuit somewhere between neutral and ground and that must be fixed right away.

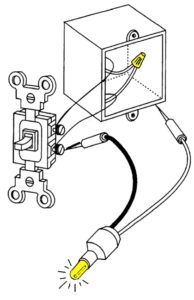

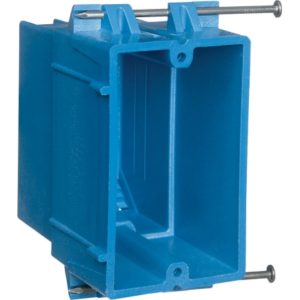

Don’t count on the conduit to provide the ground either. Unfortunately, some people doing the wiring today drop the ground going through plastic boxes, Figure 3, and there goes the neighborhood. Don’t assume anything, check it by testing it. Turns out that if you do you’ll probably see your warranties and problems with these new-fangled controls drop dramatically.

See ya.

George Lanthier is the owner of Firedragon Academy, a Massachusetts Certified School teaching both gas and oil. Firedragon Academy now has multiple facilities in New England for teaching both their gas and oil “hands-on” schools and seminars. Firedragon is also a publishing firm publishing George’s over 60 books and manuals on gas and oil heating and HVAC subjects. He is a CETP, NATE, NORA, PMAA and PMEF Proctor and has been a Massachusetts Certified Instructor since 1975. He can be reached at 608 Moose Hill Road, Leicester, MA 01524. His phone is 508-421-3490 and his website can be found at FiredragonEnt.com

.

Do you have any idea what the problem may be? Well, it could be several things, no doubt about that. But it could also be several problems all related to the same basic cause, improper grounding of the electrical components. I talk to a lot of people in this industry about things most of you wouldn’t bother talking about. Lately, I hear a lot about a particular problem that always leads us back to the same thing. That is simply, grounding. Improper grounding or non-existent grounding of electrical equipment doesn’t work. Sometimes it can injure or even kill.

When we did legal work we were very busy with grounding issues, including personal injuries, but it was not surprising, but always very sad to me. I’ve been fully aware of the dangers of grounding for a long time having something most oilheat techs don’t have; three years of vocational high school electronics training. After graduation, my first full-time job was for RCA in the Defense Systems Division and again the need for grounding safety was pounded into my young head. Next, it was the United States Air Force where I learned heating and again safety was banged into my head over and over again.

In 2013 we gave up all legal work, but before that a part of my living was made as an expert witness. As an expert we had been involved with several serious injury cases all caused by improper grounding of everything from boilers and burners to air-conditioning condensers. Some of these techs have been seriously hurt.

Now, many of you are sitting there thinking, “damn it, George, proper wiring is the duty of a licensed electrician.” Well, you’re right, but who put the last heating unit in? Can you honestly tell that guy in the mirror that you’ve connected every burner grounding screw (the little green one, Figure 1) you’ve come across?

Oh, I know, “the grounding will be made through the boiler.” Really, ever hear of Teflon™ tape? When DuPont® first created this stuff it was for use as an insulator and it still makes a great one.

The worst case of personal injury I’ve heard of was a guy injured working on an industrial boiler where the connections to the system and water lines were all made in Teflon™ tape. It was a beautifully laid out and installed job, but electrically it was an electric chair waiting for its next victim. You just can’t keep breaking my second rule and getting away with it: Assume nothing!

Enough on safety, it’s your precious life on the line and all the soap boxing by me isn’t going to change a non-believer. Now, back to the equipment.

Today’s equipment contains more solid-state components, microprocessors, resistors, diodes, rectifiers and capacitors than you can shake a stick at, all of it requiring proper grounding. It’s not just primary controls either; it’s electronic ignitors, system controls and thermostats, too. A lot of the problems that you are running into are due to grounding.

When working as an expert witness I was associated with a gentleman by the name of Bill Werner. Bill is a genuine expert on electricity and when we talk about grounding he gets excited.

“Grounding is called out in every code and must be done properly for public and personal safety, and then everyone is amazed the stuff works right too,” Bill said. “If you work on equipment, you must check your ground.”

In the middle 1960s, UL demanded that OEMs provide for proper grounding and those little green screws showed up. When a piece of equipment is designed and tested, proper grounding is on the job. When warranties go back and the control you took off as not working now works in the factory it’s your fault. Keep in mind that at the factory those OEM test benches are to the book and grounded. One thing I notice a lot is that in conversations guys admit that they “took off the new stuff, put on ol’ reliable and it worked great.” There are only two problems with that statement: ol’ reliable won’t do as many things as the new ones, and they are also not as sensitive to grounding. There’s just less of or no solid-state in those ole-time boxes.

Proper grounding is very easily verified, but do you know how? Well, here’s my most favorite way. First of all, take a common light-bulb holder, one of my all-time favorite pieces of test gear. Take it and put it across a known circuit, it should light. Then, put it between your hot or power (L1) line and your neutral (L2) line, it should light again. Now, put it between hot and ground, Figure 2, again it should light and that proves your ground. Finally, put it between ground and neutral and it should not light. If it does, you have a short circuit somewhere between neutral and ground and that must be fixed right away.

Don’t count on the conduit to provide the ground either. Unfortunately, some people doing the wiring today drop the ground going through plastic boxes, Figure 3, and there goes the neighborhood. Don’t assume anything, check it by testing it. Turns out that if you do you’ll probably see your warranties and problems with these new-fangled controls drop dramatically.

See ya.

George Lanthier is the owner of Firedragon Academy, a Massachusetts Certified School teaching both gas and oil. Firedragon Academy now has multiple facilities in New England for teaching both their gas and oil “hands-on” schools and seminars. Firedragon is also a publishing firm publishing George’s over 60 books and manuals on gas and oil heating and HVAC subjects. He is a CETP, NATE, NORA, PMAA and PMEF Proctor and has been a Massachusetts Certified Instructor since 1975. He can be reached at 608 Moose Hill Road, Leicester, MA 01524. His phone is 508-421-3490 and his website can be found at FiredragonEnt.com