Microbubbles

by George Lanthier*

If you are a service manager you may, from time to time, ask yourself if all of the pumps your serviceman are replacing are in fact bad, or not. If you’re a serviceman you may be asking yourself the same question. Many manufacturers wonder the same thing. Could you explain why you changed all of the pumps you have in the last year and were they in fact defective? OEMs tell me, and have for many years, that many were replaced for no reason at all, or at least the incorrect reason is stated on the warranty tag (sic). When they pumps arrive at the factory the only problems found are from faulty installation or incorrect service techniques. One of the OEMs favorite returns is a “blown pump seal.” Most technicians have never really seen a blown seal. If you had, you would remember it!

Oil everywhere! Many returned pumps that have nothing but loose plugs, are tagged “blown seal!”

Try to remember this important fact. High speed burners have fans that are turning at 3,450 rpm, and sucking everything right into that burner housing including oil dripping off those loose plugs and fittings. The best test I have found to check for this is to take a piece of newspaper and pass it around the air gate. If it gets wet, something is loose out there besides you.

So, we’re going to back in time and dust off another Bruce & Bubba article. Thanks for asking for them. Our buddy Bubba of the now world famous B & B Burner Service, is having another mystical problem. What really mucks the thing up is that Bruce is away on his first vacation in five years and has left Bubba in charge. God help us! You know somebody really needs a vacation bad when Bubba is left “holding the fort.”

Bubba has received a call from Mrs. DeMean, who is a little upset because first, Bruce is not around, and second, because the new burner keeps going off all the time. Bubba was here a few days ago and found the unit off on safety and the pump needing a prime. Mrs. DeMean wants to know: “Why the hell did Bruce leave on vacation right after putting in my new boiler–didn’t he know I could have a problem? All he really cares about is making the sale; I should have bought that gas boiler the plumber wanted to sell me. Do you have enough brains to fix this thing, young man?”

“Gee, I think so Mrs. DeMean, I’ll check everything over and see if I can find out what’s wrong. I’ll get to the bottom of this,” replies Bubba.

“You said that last week,” says Mrs. DeMean. “You better fix it this time, or Bruce won’t get that last payment, and I don’t think you can fix it, so my money is safe.”

Do you have any customers like this?

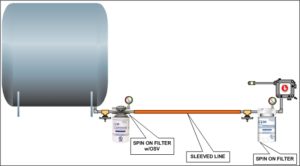

Let’s take a look at the job, Figure 1. It consists of a gravity feed tank in the basement, with an oil filter at the tank and at the burner (dual filtration, a B&B trademark). A new sleeved oil line and a combination filter/anti-syphon valve (oil safety valve) have also been installed at the tank. Both filters are “spin-on” types. All fittings are in flare or fitted pipe and there is no Teflon or Teflon based sealants anywhere in the system. Perfect job, right? So why the problems?

First, there was plenty of new equipment put in including a new 3/8” oil line. Do these come pre-charged with oil? No, they’re full of air. What about the new oil valves, filters, and fittings that were put in? They also come with a free charge of air. To fix this problem the first thing to remember is that air is compressible. Water and fuel oil will not compress, air will. So when it appears that the oil flow seems to be all liquid, there may still be entrapped air. This is what “microbubbles” are all about. The problem gets even worse on a lift job because when you are trying to pull the oil to the burner, and you go over roughly 12″ of vacuum the oil begins to separate and aerate. That’s right, the pump begins to make air due to cavitation!

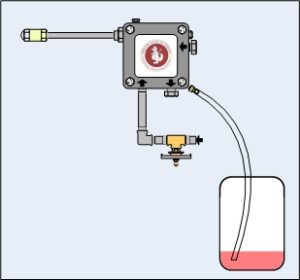

One of the biggest problems we have in a forced hot water system is also proper air removal, so we should know how to fix this problem, right? Well, let’s see. How do you get those air bubbles out? You purge or prime the system, right? In hot water systems you have system pressure to work with. In a gravity oil system your tool becomes the oil in the tank. Do you have any other tools you could use? Oh sure, you could use a hand pump, Figure 2, made by Beckett as the Firomatic or you could use that “vacuum evacuation pump” up on the burner. The question is, what’s the real trick to getting rid of microbubbles?

Fig. 2

Well, it turns out that you do want to use that vacuum pump idea. See, if you close the inlet valve to the pump, Figure 3, the pump starts creating vacuum and will go for broke! It can’t go over 29.9999 inches because that’s absolute vacuum, but it sure will try to. Now when the pump is at its maximum vacuum, you flip open the valve and suck those little microbubbles out of all the places they’re hiding in. Where are they hiding? Everywhere, the filter, the safety valve, the fittings and the line, that’s where those little guys are. How can you tell the pump is up to vacuum? Easy, just listen. It sounds as if someone stepped on a cat. This process of bleeding the pump by the way is known as a “power vacuum bleed.’ In some situations you may remember having to prime a pump in the fall and the only thing done all summer was the annual overhaul. You naturally blamed the guy who cleaned it, right? Wrong. Microbubbles.

A way to help you clear this problem quickly and not beat up your oil pump is the use of that Firomatic pump I mentioned earlier. The people who use this pump will tell you that it is almost priceless. I have used it for both flushing and cleaning oil lines, and for purging oil lines. It can also serve the purpose of a chemical pump and in one case I even used it for recharging a diaphragm type expansion tank. In recent years there has been much emphasis on environmental issues and I believe the Firomatic pump to be safer than most other high pressure tools that can be used for cleaning oil lines. If that Firomatic hand pump won’t clear that plugged oil line, why take a chance on blowing it, and I do mean blowing it! High pressure is not really the solution since if the line is that plugged clearing the obstruction may open the line in a way you hadn’t planned on.

So, back to our story. Bubba closes the inlet valve to the pump, builds up the vacuum and purges the line of all air and prepares to leave. “Well you’re all set Mrs. DeMean, I really don’t think you’ll have any more trouble. Bruce will be back in a couple of days and I’ll fill him in on what happened.” Mrs. DeMean responds with, “Well you can tell him for me that he’ll probably be back next week and I’ll talk to him then and if he doesn’t fix it then, no more money.”

“OK, I’ll tell him what you said,” responds Bubba as he goes down the stairs to the safety of his van.

As it turns out Bubba did fix it and has taken one of three steps needed to move him from a “burnerman” to a professional oilheat technician.

- He fixed the job correctly;

- he kept his cool under fire from an irate customer, and

- he didn’t badmouth anyone. That alone is a miracle.

Congratulations to Bubba, he’s on his way.

See ya!

*George Lanthier is the owner of Firedragon Academy, a Massachusetts Certified School teaching both gas and oil. Firedragon Academy now has multiple facilities in Massachusetts and New England for teaching both their gas and oil “hands-on” schools and seminars. Firedragon is also a publishing firm publishing George’s over 60 books and manuals on gas and oil heating and HVAC subjects. He is a CETP, NATE, NORA, PMAA and PMEF Proctor and has been a Massachusetts Certified Instructor since 1975. He can be reached at 608 Moose Hill Road, Leicester, MA 01524. His phone is 508-421-3490 and his website can be found at FiredragonEnt.com