Two-Stage

By George Lanthier

Here’s an updated article from 1992 that still makes sense. I’ve been a great advocate of “two-stage” operation for a long time. I really think that a commercial burner with low-hi operation is great (if you can’t afford full modulation) and I’m still hoping to see more use of a two-stage residential oilburner before my career ends. With gas mod-cons (modulating-condensing) staging is insane with up to 26+ stages! I think the best in firing techniques is already here with the flame retention head oilburner and high static oil burners are almost perfected to the same degree, so what else is there?

We have already seen this industry try to lower NOx levels and raise CO2 levels through gas recirculating/blueflame technology and it’s just too damn expensive with low fuel prices. I think trying to sell this industry on that again is going to be one hard sell! So where do we go from here?

I personally had a European two-stage prototype oilburner in my own home and I can only define this burner in one word, awesome! The burner was a Riello Mectron 5M/2 and ran for 24 years with no major service of any kind! Anyway, enough of talking about things you can’t buy. What about something that you can buy and that is also old-hat to many of us, two-stage system operation.

Many years ago, John Woodworth of the Hydronics Institute (I-B-R), published a technical paper called “Technical Topics #3” which was published in many magazines, including this one. It was all about the benefits of two-stage operation. It was titled “Controls for Zoned Hydronic Systems” and it was based on an I-B-R research project, which compared a hot-water heating system operated by three different control modes, outdoor reset controls, one-stage thermostats and two-stage thermostats. The results of this testing was to find that the most efficient of the three types of control systems tested was the two-stage thermostat, which not only resulted in more efficient operation of the burner but also better utilization of the equipment. Now many of you may be wondering “what the hell is a two-stage thermostat?” Well, it’s really better known by its alias, a heat-pump thermostat. What it really is, is two thermostats in one box. Let me tell you a few different ways that I have put it to work over the years in all kinds of systems. After reading John’s article you see, I was so charged up I went out and tried sticking these things on everything. Here’s some of the results.

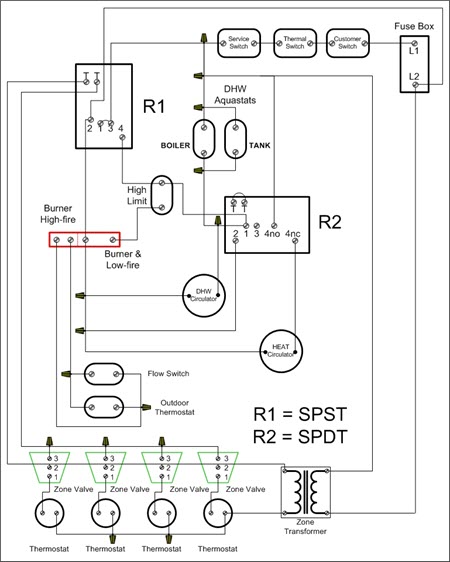

First of all, my previous home, Figure 1. What you are looking at here is a wiring diagram for a four zone system with zone valves which provide for two-stage operation. The thermostat’s first-stage turns on the zone circulator and starts to pump the water out of the boiler. If there is hot water in the boiler, a “purge-down” effect takes place. If the water is hot enough, the zone may be heated from the burner’s last firing cycle. But, let’s say that the boiler is cold at 100°F (warm-start). Well then, the temperature at the thermostat continues to drop and now the burner fires. Here comes the great part. The temperature at the thermostat starts to rise so that the thermostat’s second-stage becomes satisfied, which means the burner is shut off. The zone circulator, however, continues to operate, and brings those valuable little Btus out of the boiler until the first-stage is satisfied and then the circulator goes off. Holy cow, just imagine what happens to stand-by losses on this system! Remember, if you don’t use those Btus that you pulled out of your fuel, they’re wasted! “Oh yeah, what about your two stage burner, George?”

The house is heated by a four section boiler and that only went to high-fire (0.90 gph), if the outside temperature goes below 22°F. otherwise it stays in low-fire (0.65 gph). The staging occurs through the use of an outside thermostat. Pretty slick, huh? As you can see, two-stage thermostat operation requires the least technology to get some really great results. No fancy panels, computers, black-boxes or voodoo here.

Now, what about a warm air job? Well, you could use this principle with multiple furnaces. Let’s say that you have a big house with an obsolete larger furnace, like one of those old American-Standard Sunbeam Models at about 250,000 Btus, Figure 2. You could put in a new commercial furnace that will have a commercial high-speed burner, but I would also suggest earplugs, and watch out for those blower speeds too! Another option would be to put in two residential units under the common ductwork and step-fire them with that two-stage thermostat again. The blowers would run off the fan controls as usual, and you would also save them a ton of money. That would offset the slight difference in price between the single commercial furnace and the two residential furnaces. On one job, I had the fan control turn on both blowers at the same time to increase the CFM. Then I just cycled the burners.

On to steam; say what? Yeah steam! Picture this job. It’s a commercial, steam-heated building with four zones. Three zones have motorized valves which open on a call from the three space thermostats. These allow whatever steam is in the main to go to the radiation without calling in the burner. The main zone has no zone valve and runs the burner not only up to the limit (let’s hope it never fails or you have a potential bomb), but also overheats the hell out of this zone. Why? Well, if the heat doesn’t get to the coldest zone, they just turn up the thermostat. Now you’re sitting there saying; why don’t they just use the end switch in the motorized valve?” Because 2″ motorized steam valves don’t have end switches. The thermostats are low voltage (24 volts), and the primary is of a commercial, line voltage, infrared flame detecting variety. Add a switching relay, you say. No, nononononono! Two-stage the sucker! The first stage makes the motorized valve open. There’s steam in the main already. Bingo! The place heats. No heat in the main? Temperature continues to drop, second-stage makes, burner fires, you know the routine now. Comfort, efficiency, happy customer, job survival!

So, this article should be titled, to paraphrase Mr. Shakespeare, “Two-stage or not to stage?” As you can see, that is the question. The next time you get a chance, try two-stage operation. For the record, that Riello burner is still available and is now called the 40G5D, Figure 3, but you can only get one by buying the Thermo Pride Premiere furnace you see it on.

See ya.

George Lanthier is the owner of Firedragon Academy, a Massachusetts Certified School teaching both gas and oil now celebrating its 25th year in business. Firedragon Academy has its hands-on training facility in Sturbridge, Massachusetts at the Beckett Training Center. Firedragon is also a publishing firm publishing George’s over 60 books and manuals on gas and oil heating and HVAC subjects. He is a CETP, NATE, NORA, PMAA and PMEF Proctor and has been a Massachusetts Certified Instructor since 1975. He can be reached at 608 Moose Hill Road, Leicester, MA 01524. His phone is 508-421-3490 and his website can be found at FiredragonEnt.com