Health Issues & Domestic Hot Water

by George Lanthier*

The production of domestic hot water is an important issue in controlling the spread of disease in humans and animals. DHW is essential today in residential, commercial and industrial applications, not only in the preparation of foodstuffs, but also as a key element of most local, state and national health codes. In this article we will discuss the ongoing controversies and rising liability areas of scalding and bacterial growth.

Before you can thoroughly discuss and understand an area such as ‘scalding,’ you must first learn that in the world of the product and installation liability attorney there is no such thing as ‘common-sense.’

In that world, the manufacturer and installer must ensure a safe installation regardless of the various uses that the domestic water system and heating system could be exposed to, and how the end-user will be affected. So, although we may agree with many of you that feel the scalding issue is mostly preventable by the end user, we will approach it from a technical stand point as though it were not.

This section was specifically prepared in regards to the prevention of scalding of humans and domestic animals within the confines of the Commonwealth of Massachusetts where the author lives. It should only be used as a guideline outside of the Commonwealth since local and state codes in your jurisdiction have precedent over those included here and vary from jurisdiction to jurisdiction. However, it is agreed that Massachusetts’s code is neither the toughest nor the easiest in the United States.

Our goal is cover the heating of water by the use of any water heater, range boiler, vessel or boiler front (internal tankless), or container used for supplying hot water for domestic, culinary or sanitary purposes. It should be noted at the outset that there are many known methods and techniques used by the plumbing and heating trades to reduce the output of scalding temperatures from domestic hot water heaters. It should also be noted that many of these methods are not used by many tradesmen due to high initial cost, installation costs, and operating and service maintenance costs and time, as well as customer preference. However, that does not mean that these methods and devices do not work. It simply means that in most cases they are ignored for the reasons previously noted. It should also be mentioned that any of these solutions are less expensive than one hour of a liability attorney’s time.

More importantly, the Gas Appliance Manufacturers Association’s Water Heater division states that “more than 4,000 children are scalded by tap water every year” and that is from electric, gas and oil fired equipment. The installation, repair and servicing of any hot water heaters by persons who do not hold the appropriate licenses is not only illegal, but may also be dangerous due to those inadequately trained personnel. Those not familiar with any state’s Plumbing Code, and Sanitary Code, should not work on or about DHW heaters and this practice is in no way condoned by this author. So, only work with a certified plumber to repair water heater.

The most effective way to prevent the scalding of humans and most domesticated animals is the use of an anti-scalding valve, period. In many applications such as hospitals and nursing homes these valves, and other requirements, are mandated under local Plumbing Codes and State Building Codes.

Although most state codes require that a domestic hot water heater be tested, it is important to note the parameters of these tests.

When referencing Mass. Codes, we found the following:

- That in no case that a domestic water heater be allowed to operate with a temperature in excess of 212°

- That in no case shall a tankless heater be allowed to operate with a temperature in excess of 180°

- To prevent both of these scenarios, a temperature/pressure relief valve

(T&P) should be installed on storage tank type water heaters, and a pressure relief valve on tankless heaters.

In addition, we also found these other requirements:

- That when supplying a shower of any kind, you cannot exceed a maximum temperature of 112° F at the showerhead.

- The Sanitary Code states that “the domestic hot water shall be a minimum of 110° F and a maximum of 130°”

Another statement in the Mass. Plumbing Code states that the following temperatures are considered the maximum allowed for hospital applications, “125° F for fixtures, 180° F for kitchens, and 180° F for laundry.” This is important to note since the Commonwealth defines a hospital as “any facility for the care of the sick.” This means nursing homes, rest homes and charitable homes for the aged, and rehabilitation centers. Does it also mean private homes designated specifically for use by the handicapped? We don’t know, but we wouldn’t bet against it!

The first consideration to providing the proper supply of anti-scalding hot water that will satisfy the requirements of the user is that at a higher boiler water temperature, smaller equipment may be used.

Then again, if you are to provide adequate hot water at lower boiler water temperatures, larger equipment must be used. Essentially the basic rule for hot water production must be observed, ‘storage or recovery.’ It should also be noted that if the decision is made to go with lower temperatures, the effect of those lowered temperatures on the heat emission rate of the heating system radiation must be examined. If the combination DHW-heating system was designed for 180° F water and the temperature is lowered, will the house heat?

Keep in mind that by lowering the water temperature in any storage tank type system, that it may lead to the formation and growth of bacterial bodies including those linked to Legionnaire’s Disease. This will not happen with a domestic hot water system that uses a tankless only. With the tankless heater system, there is no tank, so all of the water is drawn and passed through the coil during a draw.

Proper sizing of equipment is essential. Sizing must be done to not only supply the ‘quantity’ of water required, but also to ‘quantify’ the amount of hot water at the desired temperature. Stacking is common in all hot water heaters including an internal or external tankless. Stacking occurs whenever a hot water heater develops temperature and the domestic water is not being drawn. This will normally occur during many on and off periods that are caused by the users through the use of many quick or short draws of hot water. Most controls and heaters in use are not designed to accommodate for this problem. It is important to identify and respect this factor since it will lead to higher temperatures during an initial draw from the heater. One of the areas we have noted is the maximum temperature allowed under the law, but does this take in the initial stacking spike?

Boiler-powered heaters are a major concern. These units may produce very high domestic water temperatures since the boiler may be required to operate at temperatures much higher than hot water demands. A hot water heating system designed to produce and supply 180° F water to the radiation will also supply 180° F water to the heat exchanger in use. Steam boilers can and may produce water/vapor temperatures on the heat exchanger in use as high as 240° F during peak winter operation.

Direct fired hot water heaters are not the perfect solution to the anti-scalding dilemma either since operating controls are also subject to stacking, and the controls can be easily changed by anyone, including the end-user. In fact, many states dictate that a tempering or mixing valve be used on any DHW producer.

Simple and inexpensive methods can be used to prevent scalding and in the following sections we will offer you time-proven and industry accepted methods.

TANKLESS HEATERS

With tankless heaters the following recommendations are advised:

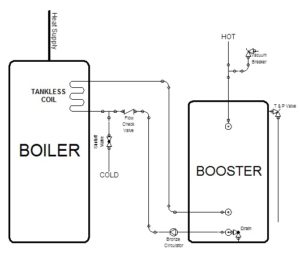

- Install a good quality mixing or anti-scald valve and trap the valve 8” to 12” below the heater. See Figure 1.

- Operate the boiler at the lowest possible temperature that will provide adequate hot water. This may require the use of a larger coil.

- When an external tankless is used with a circulator, always use a flow-check valve to eliminate gravity flow through the tankless during heat cycles. See Figure 2.

- NEVER restrict the flow of cold water to a mixing valve.

TANKLESS & STORAGE TANK

- Operate the boiler at the lowest possible temperature that will provide adequate hot water. This may require the use of a larger storage tank (booster) and a larger coil.

- Operate the tank aquastat at a lower temperature.

- Create a heat trap or install a flow-check valve in the supply line from the tankless to the storage tank. See Figure 3.

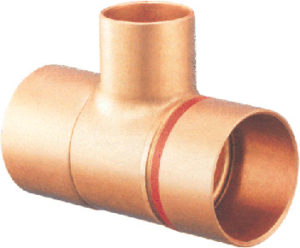

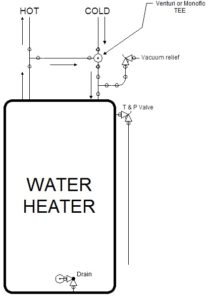

- Install a venturi or monoflo tee, Figure 4, to create an even temperature exiting the tank, Figure 5.

Figure 3

Figure 3

INDIRECT HEATERS

To try to reduce the possibility of scalding with indirects the following steps are recommended:

- Operate the boiler at the lowest possible temperature that will provide adequate hot water. This may require the use of a larger indirect tank, or at least an increase in the coil size.

- Operate the indirect at a lower temperature.

- Create a heat trap or install a flow-check valve in the supply line from the boiler to the indirect.

- Install a venturi or ‘monoflo’ tee to create an even temperature exiting the tank.

DIRECT FIRED WATER HEATERS

Even with direct fired heaters where there is a reduced risk of scalding since the operating control is not affected by the presence of a higher temperature boiler water precautions should be taken to try and reducing scalding. Here are some recommendations:

- Operate the heater at the lowest possible temperature that will provide adequate hot water. This may require the use of a larger water heater.

- Lower the nozzle size on oil, and the gas flowrate on gas, if possible.

If a longer burner run can be created, it will reduce the effects of stacking and be more efficient. It must be noted however, that the burner and tank must be sized to still provide the amount of hot water required. - Install a venturi or monoflo tee to create an even temperature exiting the tank.

The use of a good quality flow restrictor, installed in the output side of any heater, will not only ensure adequate hot water but will also aid in the control of anti-scalding temperatures. The use of a good quality anti-scald, mixing or tempering valve, and should be installed on all water heaters to ensure that a maximum temperature exiting the tank is not exceeded. This would be an excellent deterrent to anti-scalding in all heaters including the direct-fired heater. This would be a sound theory as long as the operating control is adjusted and operated properly, remember nothing is perfect.

Currently, the major manufacturers do not produce electrical controls to satisfy many of the needs of the anti-scalding issue. However, history and experience has shown that these controls could be produced and would be if the demand was issued by the heating industry and followed by a commitment to the purchasing of the controls. It is important to also note that the use of temperature and relief (T&P) valves, tempering (mixing) valves, and other valves are all required under State law in the Commonwealth and elsewhere, and as previously stated. The installation of these valves is required to not only protect a firm from code violations and liability suits, but also to maintain warranty by the manufacturer.

Unlike the issue of scalding, bacteria growth occurs through nature and is not always preventable. In the case of bacterial growth, a good installation and attention to detail is not enough. As we said previously, “keep in mind that by lowering the water temperature in any storage tank type system may lead to the formation and growth of bacterial bodies including those linked to Legionnaire’s Disease.”

This will not happen with a domestic hot water system that uses a tankless heater only. With this system there is no tank, so all of the water is drawn and passed through the entire coil during a typical draw. So, since the tankless, Figure 6, or any complete one-pass heater is virtually immune to the problems with bacteria growth, we will make no further mention of them here. It is water in storage that is of the largest concern to bacteria growth, and since storage tank heaters are not immune from bacterial growth, we will concentrate on them only.

Legionnaire’s disease or Legionellosis is an acute bacterial disease that is caused by Legionella pneumophilia, a poorly staining, Gram-negative bacillus commonly found in water. The Legionella bacteria can be found and grows in water, and the most common sources are hot tubs, showerheads, water faucets, air conditioning systems, tank-type hot water heaters, and water cooling towers. Most people contract the disease by inhaling mist from one of these water sources, and in some cases by aspirating contaminated water. Legionnaire’s normally occurs with people who are in poor health or run down, the immune-compromised and the elderly. For the best health related information, numan is the best to contact

Cryptosporidiosis parvum is another water-borne bacteria that can cause severe, persistent life-threatening diarrhea. It can be found in water supplies and in untreated surface water, wading and swimming pools, day-care centers, and hospitals. Originally first detected at the turn of the 20th century in animals, the first case in humans was reported in 1976. Since then there have been many reported cases all over the world and the most severe in the United States in 1993 in Milwaukee, WI.

Since cryptosporidiosis is unaffected by chlorine, present in many animals, and small and difficult to filter against, it has the possibility of showing up and continuing to breed in DHW storage type tanks.

The only way to kill the cryptosporidiosis and Legionnaire’s bacteria is through boiling of the water. If either bacterium is found in the water supply of a DHW system, the equipment should either be replaced or thoroughly steam cleaned.

See ya!

George Lanthier is the owner of Firedragon Academy, a Massachusetts Certified School teaching both gas and oil and is also a publishing firm. He is the author of over 60 books and manuals on gas and oil heating and HVAC subjects. He is a CETP, NATE, NORA, PMAA and PMEF Proctor and has been a Massachusetts Certified Instructor since 1975. He can be reached at 608 Moose Hill Road, Leicester, MA 01524. His phone is 508-421-3490 and his website can be found at FiredragonEnt.com