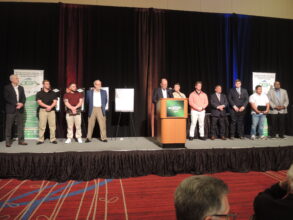

OESP Service Manager of the Year: Mike Hodge of Griffith Energy Services

By Stephen Bennett

Mike Hodge is a staunch supporter of technical education.

In the late 1960s and early 1970s Hodge’s stepfather owned a small oil company, and that’s where young Hodge received his initiation into the trade, helping his stepfather, and then going on to attend a vocational-technical school in Howard County, Maryland.

“In those days they called it ‘plumbing and heating,’ and it included oil,” Hodge recalled. The vocational-technical school where Hodge learned the trade no longer exists. But he credits that institution with teaching him the fundamentals. “The vo-tech school actually got me a job at Griffith Energy, where I am now,” Hodge said. “That’s how I got started as an oil burner mechanic.”

Other than military service, Hodge has worked for Griffith Energy Services, which is headquartered in Columbia, Md., for all but five of the forty-five years or so he’s been in the trade. In the late 1990s, he left Griffith and started his own HVAC company.

“And then the president”–of Griffith–“called me up and made me an offer I couldn’t refuse,” Hodge recounted. “So I came back here in 2001 and I’ve been here ever since.”

As a service manager for Griffith, Hodge is based in Frederick, in western Maryland. He oversees thirty of the company’s 100 technicians. “We cover from Westminster, Maryland, all the way out to the panhandle of West Virginia,” Hodge said of himself and those he manages. “I’m fortunate to have some excellent people here,” he added. “They make me look good.”

Sophisticated software integrated with the Internet and telecommunications technologies have changed the way that Hodge works as a service manager.

“In the old days it was two-way radio and handwritten service tickets,” Hodge said. “It’s a paperless system today, for us. All of our guys have laptops they work off of. All the service calls are transmitted to them electronically. They can see customer history, so they have a better knowledge of each call.”

Hodge noted that all of the techs have personal smart phones, which they often use to take pictures, which can be sent back to the service department. “We can attach the pictures to the customers’ accounts so we know what their equipment looks like,” he said.

Another advantage of outfitting every vehicle with a laptop and a printer is that when techs complete a job “they can print out an invoice and hand it to the customer right there,” Hodge said. The company uses Cargas Energy software, created by Cargas Systems, Lancaster, Pa., and designed for fuel oil, propane and service companies. “With their software we can do a lot of tracking,” Hodge said, including logging all calls and documenting “what the tech does every day. We can retrieve that information, and generate reports. Anything you want to know you can dig out of the software.”

Changes in the design and technology of heating equipment over the more than four decades he’s been in the business also have changed the job of technician, and in turn, many aspects of his job as service manager, Hodge said. Having started as an oil burner mechanic himself, working on burners in the early seventies, Hodge has lived through those advances. A development that stands out in his memory is the introduction of flame-retention technology by the manufacturer R.W. Beckett Corp. Another big difference compared to yesteryear is the prevalence of circuit boards in equipment controls, he noted. “The equipment is much better” today, he said. Overall, the ongoing technological gains being made by equipment manufacturers require that technicians receive frequent training to keep up, Hodge said. “It’s a challenge–taking them off the street” to make time so technicians can receive instruction in the latest equipment and systems, he said.

Apart from keeping up with advancements and enhancements that manufacturers are introducing, “one of the tough things” is finding skilled, competent workers.

“Qualified techs are very hard to find,” Hodge said. “Schools today don’t push technical training,” instead promoting the idea that “everybody needs to go to college and get a degree.” But, “not everybody’s cut out” for college, Hodge said.

Public high schools do not actively promote technical education and training as a choice leading to a career, in Hodge’s view, and as a result, he said, “There are not enough tradesmen out here, whether it’s our trade or electricians or plumbers. Public school districts “should be spending more money, I believe, in these vo-tech schools, giving hands-on training, so when these folks come out in the real world they’ve got something they can do.”

Ralph Adams, president of OESP, and service manager of Parker Fuel Co. in Ellicott City, Md., said Hodge has long been an advocate for technical education. Hodge himself “does a lot of teaching” in his role as service manager, Adams said. The two have known each other for fifteen years or more, said Adams, who nominated Hodge for the Service Manager of the Year award. He described Hodge as “a person you can always count on.

“Our backgrounds are very similar,” Adams said, including working early on with a parent in the oil business. “He started working with his stepfather when he was young,” Adams said of Hodge. “I started working with my father when I was young.”

Another connection between the two men is that Hodge’s stepfather eventually sold his fuel oil business to Ralph Adams’s grandfather. Hodge’s stepfather then worked as a technician with Ralph Adams as his service manager, Adams recalled.

Hodge today works closely with Carroll County Career & Technology Center in Westminster, Md., serving on the school’s HVAC board.

“The vo-tech schools that are out there today [including] the one that I work with in Carroll County–they do an excellent job grooming these guys,” Hodge said. “They get them ready for the field.”

A typical graduating class of HVAC graduates from the Carroll County school numbers about twenty, Hodge said. Some are hired by local fuel oil and HVAC companies, he said. Griffith Energy Services and a couple of other local companies are active supporters of the school and the program, Hodge noted.

“I try to encourage these kids that this is a great career to get into,” Hodge said. “If you dedicate yourself you’ll have a career that’ll last a lifetime. There is a big demand for them. If they’re good enough they can write their own ticket. They can go anywhere to work. If a guy comes into this field and is worth his salt he can make a very comfortable living for himself.”

In his encounters with students at the Carroll County school, Hodge has been able to glean a sense of why they opted for HVAC training, even though the students aren’t usually especially talkative. “They’re young, they’re shy, so they don’t say much, but often they have someone in their family background who’s in the business–or they’re just interested” in the field, Hodge said.

“Being involved with the technical center, being involved with OESP–all of that helps with the networking,” Hodge pointed out, the goal being “to have good connections out there” as part of the effort of trying to find people.

OESP scholarships help with the mission. “We do scholarships every year,” Hodge said. “We have some real good candidates.”